Isothermal (constant temperature) machining room

Temperature change is an archenemy to precision machining, and we minimize the influences on materials and machines by maintaining a constant temperature in our factories. Ultra precision machining is realized in our isothermal machining room, where the temperature is kept at 24℃±0.5℃ (summer) and 20℃±0.5℃ (winter).

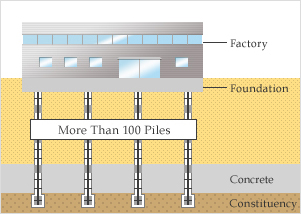

In machining rooms, vibration control is important along with temperature control. In order to realize accurate and reliable machining work, our machining room boasts a 1 meter thick concrete floor, with more than 100 piles underneath the floor to support machines in the room.

5-axis machine tools for flexible work

5-axis machine tools are essential to work on products with complicated shapes and surfaces. We introduced state-of-the-art tools made by HERMLE (Germany) and YASUDA PRECISION TOOLS (Japan), and have been pursuing speed and accuracy.

Clean room

Precision assembly and evaluation are carried out in a temperature controlled clean room.

U-Corporation has sixty-one machining centers and milling machines in total.

The total number exceeds one hundred including lathes, grinders, and EDMs (electric discharge machines). With these machines, we can accept clients’ requests for short lead time.

Machining centers and milling machines【61】

| TYPE | MODEL | MANUFACTURER | SPEC |

|---|---|---|---|

| 5AXIS MACHINING CENTER | C30U | HERMLE | 650x600x500 |

| 5AXIS MACHINING CENTER | H30i | YASUDA | 650x560x560 |

| VERTICAL MACHINING CENTER | YBM-950V | YASUDA | 900x500x350 |

| VERTICAL MACHINING CENTER | YBM-640V | YASUDA | 600x450x350 |

| VERTICAL MACHINING CENTER | V33 | MAKINO | 600x400x350 |

| VERTICAL MACHINING CENTER | F-MACH | TOSHIBA | 400x400x250 |

| VERTICAL MACHINING CENTER | OTHERS |

Lathes and grinders【12】

| TYPE | MODEL | MANUFACTURER | SPEC |

|---|---|---|---|

| HORIZONTAL MACHINING CENTER | A55 | MAKINO | 500x500x500 |

| HORIZONTAL MACHINING CENTER | SH400 | MORISEIKI | 500x400x400 |

| MULTI TASKING MACHINE | INTEGREX | MAZAK | φ660 |

| MULTI TASKING MACHINE | NT4200 DCG | MORISEIKI | φ660 |

| MULTI TASKING MACHINE | NTX2000 | MORISEIKI | φ660 |

| CNC LATHE | NL2000/1500 | MORISEIKI | φ300 |

others【20】

| TYPE | MODEL | MANUFACTURER | SPEC |

|---|---|---|---|

| ULTRA PRECISION NC LATHE | UPL-240 | RIKEN | φ400 |

| CNC MILLING MACHINE | AE74 | MAKINO | 700x300x400 |

| CNC MILLING MACHINE | AN-SRN | SHIZUOKA | 700x300x400 |

| WIRE CUT EDM | EVOLUTION | AGIE | 400x300x250 |

| WIRE CUT EDM | ROBCUT α-1ID | FANUC | 600x400 |

| WIRE CUT EDM | AW300 | SODICK | 300x300x150 |

| WIRE CUT EDM | AW500 | SODICK | 500x300x200 |

| DIE SINKING EDM | AQ35L | SODICK | 350x250x250 |

| SURFACE GRINDER | NP415-F | NAGASHIMA | 400x150x300 |

| SURFACE GRINDER | SPG-DX63 | OKAMOTO | 600x300 |

| LAPPING MACHINE | TR15S-F0DT | TECHNO RISE | φ150 |

| INJECTION MOLDING MACHINE | J100EⅡ-P | SUMITOMO | 100ton |

Measurement equipment

In addition, we have introduced state-of-the-art measurement equipment for the evaluation of micrometer-order precision parts. Measurements and evaluations are carried out by our experts in order to guarantee required quality.

| TYPE | MODEL | MANUFACTURER | SPEC |

|---|---|---|---|

| COORDINATE MEASURING MACHINE | SVA FUSION | TOKYOSEIMITU | 900x600x600 |

| COORDINATE MEASURING MACHINE | F604 | MITUTOYO | 600x400x300 |

| COORDINATE MEASURING MACHINE | HB-504 | MITUTOYO | 500x400x250 |

| COORDINATE MEASURING MACHINE | QM MEASURE | MITUTOYO | 300x500x300 |

| VIDEO AND MULTISENSOR | SMARTSCOPE | OGP | 300x250x150 |

| LASER MICROSCOPE | VK8550 | KEYENCE | |

| MICROSCOPE | NIKON | ||

| ROUNDNESS & CYLINDRICAL MEASURING INSTRUMENT | RONDCOM54 | TOKYOSEIMITU | φ300 |

| SURFACE ROUGHNESS MEASURING INSTRUMENT | SURFTEST | MITUTOYO | |

| HOLTEST | ETALON | φ5-φ100 | |

| BORE GAUGE | MITUTOYO | φ20-φ150 | |

| PIN GAUGE | CERAMIC | MITUTOYO | φ0.2-φ10 |

| BLOCK GAUGE | CERAMIC | MITUTOYO |

CAD/CAM

It is also possible to manufacture a product from data by utilizing and carrying out CAD data.

| TYPE | MODEL | MANUFACTURER |

|---|---|---|

| 3D CAD/CAM | NX | Siemens PLM Software |

| 3D CAM | Hyper Mill | OPEN MIND Technologies |

| 3D CAM | Mastercam | CNC Software, inc. |

| 3D CAD | think3 | think3, Inc. |

| 3D CAD | Creo Elements/Direct Modeling | PTC |

| 3D CAD | Solid Works | SolidWorks |

| 2D CAD | Auto CAD LT | Autodesk |

Security System

In our factory, each door has an individual security lock to prevent outsiders from entering into the rooms, thereby avoiding information leakage from telecommunication devices.