Origin of our technologies: lathe and milling

Although leading edge mechatronics is important, we believe general-purpose equipment is the basis of machining work. From this point of view, we encourage our staff to take technical skill examinations as a part of our engineer training efforts. Most of the staff in our manufacturing division are engineers certified in lathe, milling, and grinding operation.

We excel at precision machining of rare metals

Rare metals are known to have various kinds of functions. We manufacture precision parts from difficult-to-cut materials such as titanium, inconel, cobalt, molybdenum, super invar, and permalloy.

【Correspondence】

| Metal | Resin | Rare Metal | Brittleness |

|---|---|---|---|

| AI | ABS | Tantalum | Silica glass |

| SUS | PC | Kovar | Aluminium oxide |

| SK | POM | Invar | silicon wafer |

| NAK | PMMA | Inconel | carbon・silicon |

| SC | PBT | permalloy | ceramics |

| SS | PPS | Monel | |

| brass | PEEK | nickel alloy | |

| titanium alloy | PP | Pt | |

| copper alloy | Nylon | cobalt alloy | |

| magnesium alloy | PTFE | Cemented Carbide |

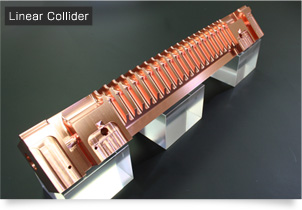

Linear Collider

We manufactured an accelerating tube for KEK, the High Energy Accelerator Research Organization. The tube is made from pure copper and boasts ±2.5μm accuracies in contour, parallelism, flatness, and verticalness. These measurements are subject to variation through small temperature change, but extremely high accuracies are realized by our technologies and facilities.

For more information about a linear collider, please visit:https://clic.cern/